Amaco LG-Series Low Fire Gloss Glazes:

Amaco Gloss Glazes come in 48 vibrant shades, each firing to a brilliant high-gloss finish suitable for a variety of ceramic works. These colors can be combined or layered to achieve custom hues. After firing, the glaze produces a smooth, satin-like surface. The low-fire formula promotes glaze flow, effectively masking surface imperfections for a refined final appearance.

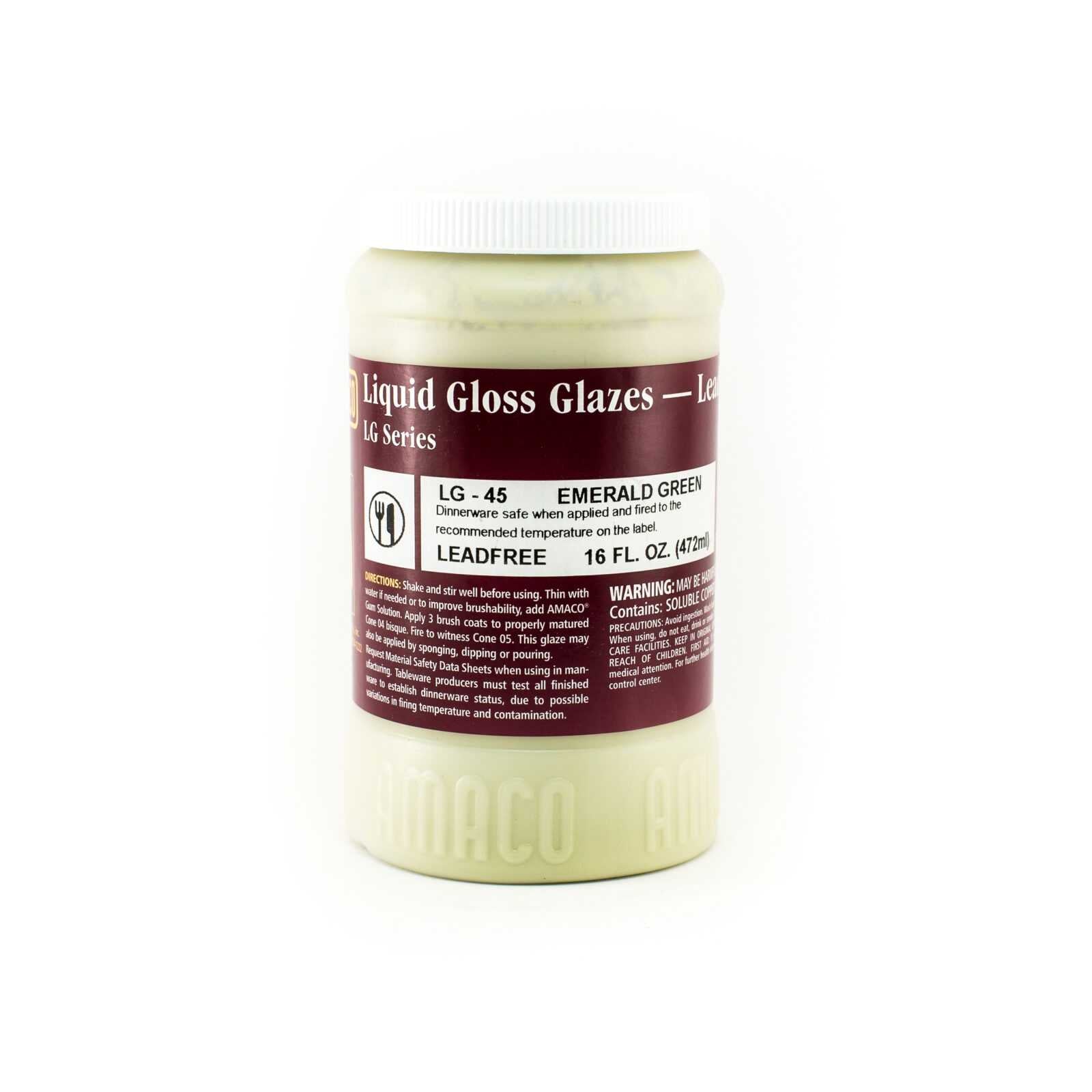

Most Amaco Gloss Glazes are lead-free, making them appropriate for food-safe applications. However, a few exceptions exist, so it is important to verify the suitability of each glaze before applying it to dinnerware.

Firing at Cone 06-04, Amaco® Gloss Glazes achieve a smooth, glossy surface at Cone 05 (1915°F, 1046°C). These glazes exhibit slight flow during firing, producing a high-gloss finish that helps to mask application flaws. They perform well on a wide range of ceramic clays and slips.

LG-10 produces a smooth, high-gloss finish when fired to a mature witness Cone 05 (1915°F, 1046°C). For optimal results, apply the glaze slightly thinner than normal, with two coats typically providing sufficient coverage.

A clear glaze can be applied over the AMACO® LUG series, Velvet, Velvet-1-Strokes, Designer Velvet, and GDC Gloss decorating colors. When using gloss decorating colors on bisque, a clear gloss glaze is required, applied simultaneously and fired once. LG-11 Opaque White is the most opaque and brightest white glaze, ideal for the Majolica technique. Apply LG-11 on a mature Cone 04 (1940°F, 1060°C) bisque, then paint your design with GDC Gloss Decorating Colors over the unfired white glaze. Once complete, fire the piece; no additional clear glaze is needed over the GDC design when using a white glaze base.

All AMACO® glazes are designed for brushing application. However, when working with lead-containing glazes using pouring, sponging, or dipping methods, it is advisable to wear rubber gloves to prevent glaze contact with the skin and reduce the risk of lead ingestion through hand-to-mouth transfer.

For optimal results with these glazes, a rapid firing cycle of 3-4 hours is essential, not exceeding Cone 06 (1830°F, 999°C). Adequate airflow during firing is critical; ensure the kiln is loaded with ample space around each piece to allow proper circulation. Avoid overcrowding, keep peepholes open throughout the firing, and, if necessary, leave the kiln door slightly ajar to maintain a consistent oxygen supply.

Copper green glazes can negatively impact red glazes when fired in close proximity. To prevent this, keep pieces glazed with green colors well separated from those with red glazes. By following these guidelines carefully, you can ensure the vibrant and high-quality results characteristic of AMACO® products.

Amaco® provides three white gloss glazes, each delivering distinct finishes upon firing: DG-11 Deco White results in a pure white, LG-11 produces a white finish, and F-11 White yields an off-white tone.